24/7 Lift Maintenance Repair: Prompt and Effective Solution

24/7 Lift Maintenance Repair: Prompt and Effective Solution

Blog Article

Opening the Secrets to Efficient Lift Fixes: Specialist Insights Revealed

In the realm of lift repair and upkeep, revealing the approaches that lead to efficient and reliable service is akin to figuring out an intricate puzzle. As we get started on this trip to demystify the secrets behind streamlined lift repair work, a globe of opportunities arises, guaranteeing a future where downtime is minimized, safety is focused on, and operational quality ends up being the norm.

Typical Lift Repair Obstacles

An additional common difficulty in lift repair work is the lack of correct upkeep records. Without exact maintenance records, repair service technicians might have a hard time to detect concerns properly or anticipate possible issues. This can lead to longer fixing times and increased prices as specialists function to repair problems without historical information to guide them.

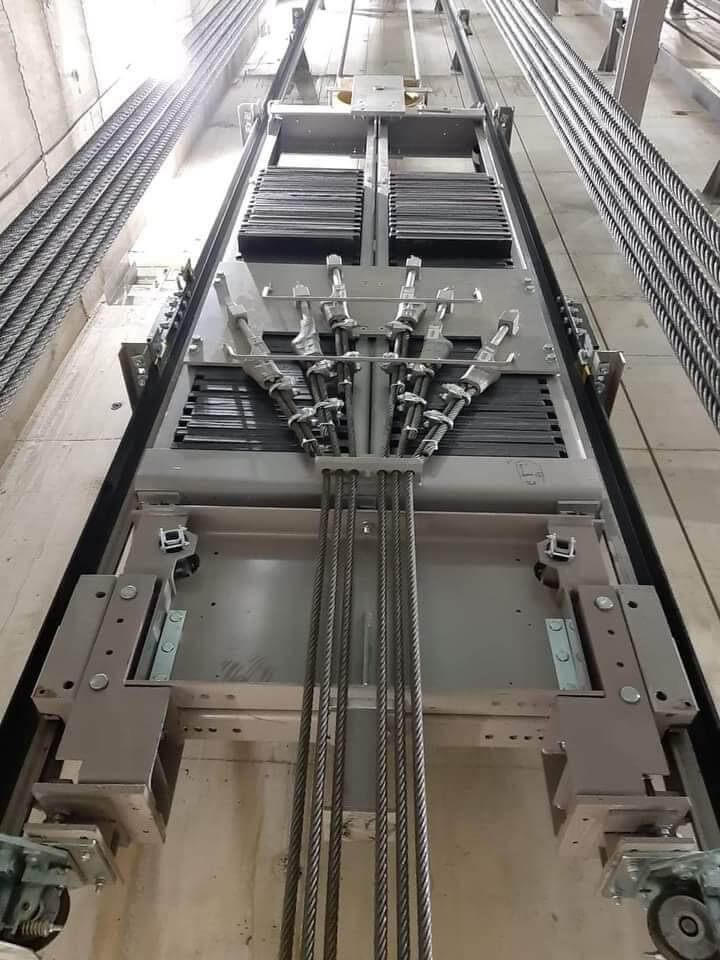

Moreover, access issues within lift shafts can posture significant obstacles during repairs. Minimal room, unpleasant angles, and intricate machinery can make it tough for professionals to get to the essential components for repair, prolonging the total repair procedure - Lift Maintenance Repair. By dealing with these typical difficulties proactively, lift repair service specialists can enhance functional performance and guarantee the smooth functioning of upright transportation systems

Proactive Upkeep Methods

Applying aggressive maintenance methods is extremely important for making certain the durability and ideal performance of lift systems. By embracing an aggressive method to upkeep, structure managers and lift maintenance teams can deal with prospective issues prior to they rise into costly repair services or downtime. One effective technique is to establish a routine maintenance schedule that includes comprehensive inspections, lubrication of moving parts, and testing of safety functions.

Additionally, spending in training programs for maintenance team can improve their skills in determining prospective problems and executing precautionary maintenance jobs properly - Lift Maintenance Repair. By equipping maintenance groups with the expertise and tools needed to proactively maintain lift systems, structure owners can lessen disruptions, expand the lifespan of their lifts, and ensure a trusted and safe upright transportation experience for residents

Repairing Methods

Reliable repairing techniques are important for quickly recognizing and dealing with issues with lift systems to minimize downtime and guarantee ideal performance. When faced with a lift breakdown, methodical troubleshooting is important to identify the origin accurately. One reliable strategy is to begin with a thorough visual inspection of the lift components, looking for any kind of visible indicators of wear, misalignment, or damages. Additionally, making use of diagnostic devices and software can aid in recognizing digital or sensor-related concerns that might not be promptly obvious.

Enhancing Fixing Abilities

Enhancing effectiveness in lift system repair services is an essential facet of ensuring optimal capability and reducing functional interruptions. Lift technicians must continually work on developing their repair skills to meet the demands of modern lift systems.

In addition, remaining upgraded with the most recent innovations in lift innovation is essential for professionals wanting to enhance their repair service skills. This includes proactively inquiring about new elements, software updates, and upkeep strategies to efficiently identify and remedy problems. By spending effort and time right into continuous knowing and useful experience, lift service technicians can substantially boost their repair expertises and add to the efficient performance of lift systems.

Elevating Maintenance Standards

Elevating upkeep criteria in lift systems is paramount for making sure prolonged click resources functional effectiveness and security. Normal maintenance not only improves the efficiency of lift systems yet also decreases the danger of unexpected malfunctions and ensures the security of individuals. By adhering to strict maintenance protocols, lift owners and operators can considerably lower the likelihood of pricey repairs and downtime.

Implementing a comprehensive upkeep routine that consists of regular examinations, lubrication of relocating parts, and positive substitute of worn elements is crucial. Using advanced technologies like IoT sensors and predictive upkeep software can help in monitoring the lift's condition in real-time, allowing timely treatments before concerns intensify. Furthermore, giving constant training for maintenance personnel on the most up to date sector criteria and best methods is important for maintaining upkeep excellence.

Furthermore, promoting a society of accountability and attention to information among upkeep groups can additionally boost upkeep standards. Motivating open communication channels for addressing and reporting upkeep concerns immediately can help in keeping a high degree of lift system reliability. Ultimately, by focusing on and raising upkeep criteria, lift systems can operate effectively and securely for an extensive duration.

Final Thought

In final thought, reliable lift repair work require aggressive upkeep methods, repairing methods, and improved repair skills. By boosting and dealing with typical difficulties upkeep criteria, upkeep experts can effectively make sure the smooth procedure of lifts - Lift Maintenance Repair. Implementing these professional understandings can cause boosted efficiency, decreased downtime, and raised security for both guests and equipment

In the realm of lift repair service and maintenance, revealing the techniques that lead to effective and efficient solution is similar to deciphering an intricate puzzle.Another widespread useful content difficulty in lift repairs is the lack of appropriate maintenance documents. By embracing an aggressive strategy to maintenance, structure supervisors and lift maintenance groups can deal with possible problems before they rise right into costly repair work or downtime.In conclusion, efficient lift repair services need aggressive upkeep techniques, troubleshooting strategies, and improved repair work abilities. By boosting and addressing usual difficulties upkeep requirements, maintenance professionals can effectively ensure the smooth procedure of lifts.

Report this page